L'usinage CNC modifie directement la taille, la forme, la position mutuelle, la rugosité de surface ou les propriétés des matières premières ou des produits semi-finis pour en faire des produits finis.

Y compris: les procédés de moulage, de soudage, de galvanoplastie, de traitement thermique, d'usinage et d'assemblage.

Le processus d'élimination du matériau de surface de la pièce par découpe du métal, le processus d'obtention du produit fini est appelé un processus d'usinage.

D'une manière générale, un processus d'usinage fait normalement référence au processus d'élimination du matériau de surface de la pièce et d'obtention du produit fini. Cependant, afin d'obtenir un produit bien raffiné, les gens ont été habitués à prendre de nombreuses mesures et l'ensemble du processus pourrait prendre un temps relativement long. Alors que, comme l'usinage de précision CNC a finalement fait son entrée dans l'industrie, cette situation a été grandement améliorée.

Capable d'effectuer une variété de processus tels que la coulée, le soudage, la galvanoplastie, le traitement thermique, l'usinage et l'assemblage, l'usinage de précision CNC peut directement changer la taille, la forme, la position, rugosité de surface et autres propriétés des matériaux bruts ou semi-finis et les transférer tous dans des produits finis bien finis et raffinés. Par conséquent, après avoir résolu les problèmes de traitement de pièces complexes, précises, en petits lots et multi-variétés, d'usinage de précision CNC ou de fraisage de précision CNC, est maintenant progressivement devenu une partie importante dans le traitement des métaux. Et en tant qu'usine professionnelle d'usinage de précision CNC, EMP Tech peut vous fournir le meilleur service CNC en aluminium en Chine.

Lorsque la matière première est placée pour le processus d'usinage et les services de fabrication, la surface du matériau doit être traitée en premier afin de fournir une référence fine pour le traitement du processus ultérieur.

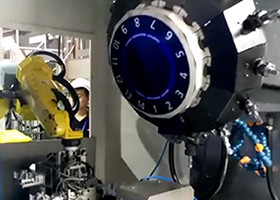

Le traitement d'une surface de haute qualité avec fraisage CNC de précision peut normalement être divisé en 3 étapes de traitement: l'ébauche, la semi-finition et la finition. Avec le réglage de ces étapes de traitement, le tournage et le fraisage CNC peuvent alors être effectués de manière précise et claire.

Quant à la production de pièces en aluminium précises et petites, telles que des supports et des bielles, les trous finis dans l'avion doivent d'abord être usinés par la machine CNC. Ce faisant, ces premiers trous usinés peuvent alors fonctionner efficacement en tant que références précises pour le positionnement des étapes suivantes.

La finition de la surface principale (telle que le meulage, le meulage fin, le laminage, etc.) doit être effectuée au stade final du processus. Et il convient de noter que pendant cette étape, les pièces traitées doivent être traitées avec soin car toute légère collision peut endommager la surface.

Technologie de fabrication avancée

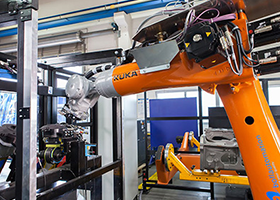

Équipement de traitement automatisé de haute précision et à haute efficacité

Technologie logistique avancée

Technologie de contrôle avancée

Technologie de gestion moderne

Quant aux machines CNC, elles ont une forte adaptabilité en termes de traitement des objets. Ils peuvent fournir des méthodes de traitement appropriées pour la fabrication de divers moules.

Le service de fraisage CNC présente également les caractéristiques d'une précision de traitement élevée et d'une qualité de traitement stable.

Étant donné que l'usinage CNC de précision est contrôlé par des ordinateurs, la liaison multi-coordonnées peut être facilement réalisée par des machines CNC, et des pièces aux formes complexes peuvent également être traitées.

Les services de programmation CNC en aluminium possèdent également la qualité d'une grande flexibilité. Lorsque la conception des pièces en aluminium CNC personnalisées sera modifiée, les gens n'auront qu'à modifier le programme NC dans la machine CNC et l'ensemble du processus d'usinage sera modifié en conséquence.

Étant donné que la machine-outil est hautement automatisée, l'intensité du travail peut alors être considérablement réduite.

Propice à la modernisation de la gestion de la production, les machines-outils CNC utilisent des informations numériques et des codes standard pour traiter, transmettre des informations, et utiliser des méthodes de contrôle informatique pour remplacer les bases de l'intégration de la conception, de la fabrication et de la gestion assistées par ordinateur.

La production de pièces de petit lot et d'aluminium CNC personnalisé

La production de pièces en aluminium qui doivent être modifiées plusieurs fois

La production de pièces de travail avec des exigences de précision d'usinage élevées

La production de pièces coûteuses, qui peuvent coûter d'énormes pertes économiques une fois qu'elles sont mises au rebut